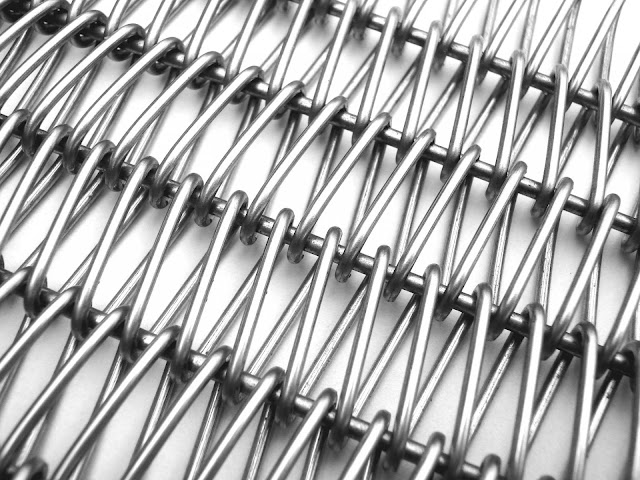

CHARLIE BRAVO is a specific metal mesh with small openings. Characterized by oval spirals with multiple waved cross rods.

Applications: wall and ceiling panels, interior decorations, façade covering, jewellery, creative modern furniture.

Material: stainless steel

Dimensions: ↔6 mm:↕ 6 mm; ∅ 0,9/1 mm

Weight: 8,7 kg/m2

Finish: matt, glossy, coloured

Width: maximum width: 4000mm

Open area: 38%

On request:

- other materials: bronze, copper, silver, gold.

- other dimension

- flat wire

ROMEO SIERRA SMALL is an architectural metal mesh characterized by a round spiral with looped edges.

Applications: wall covering, ceiling panels, façade covering, railings.

Material: stainless steel

Dimensions: ↔ 3 mm; ↕ 15 mm; ∅ 1,2/2 mm

Weight: 11,5 kg/m2

Finish: matt, glossy

Width: maximum width: 4000mm

Open area: 48%

On request:

- other materials: bronze, copper, silver, gold.

- other dimension

- welded edges

- flat wire

Thursday, 16 July 2015

Tuesday, 14 July 2015

Promesh - Ring Mesh & Scale Mesh

Promesh GmbH has been producing and developing ring mesh and scale mesh

for architectural applications since 2006. The claim to quality,

function and design that is unique to alphamesh of constantly realising

new ideas for application with visionary force. As a new original

material alphamesh fascinates today in the most diverse architectural

and design application areas, from very small to very large. Since size

is what makes alphamesh unique worldwide. This is made possible thanks

to a special manufacturing process, which enables almost unlimited

dimensions and therefore unimaginable scope. As a facade cladding in

building dimensions, as a light shell structure or as an interior design

element alphamesh always impresses with its option of redefining the

term space, as the transition from flat two dimensionality into a

shaping 3rd dimension is natural for the flexible material. alphamesh

uses light and water as a stage for its own production, with reflections

here and the modulation of flowing dynamics there. And because

alphamesh's range of application is as diverse as the ideas that

architects and planners associate with it, alphamesh is not just a

product but rather an unlimited creative design process.

Steel Promesh

Steel Promesh

material description

Type 4.2 ringmesh / chainmail is made of high quality stainless steel wire. Each individual ring is welded and guarantees the high strength and stability of the metal mesh. Its extremely high resistance and durability permits any exterior or interior application.

Custom-made measurements on specific request.

- wire gauge: 0.55 mm

- external ring diameter: 4.2 mm

- tensile strength: > ca. 150 N/ring

- rings per sqm: ca. 123975

- haptic: textile floating, soft to the touch

Brass Promesh

material description

Scale mesh consists of single scales which are interlinked with a ring to a light flexible metal mesh.

Custom-made measurements on specific request.

- scale diameter: 5,8mm

- material: brass

- haptic: textile flowing, soft to the touch

From: http://www.stylepark.com/en/manufacturer/promesh

Steel Promesh

Steel Promeshmaterial description

Type 4.2 ringmesh / chainmail is made of high quality stainless steel wire. Each individual ring is welded and guarantees the high strength and stability of the metal mesh. Its extremely high resistance and durability permits any exterior or interior application.

Custom-made measurements on specific request.

- wire gauge: 0.55 mm

- external ring diameter: 4.2 mm

- tensile strength: > ca. 150 N/ring

- rings per sqm: ca. 123975

- haptic: textile floating, soft to the touch

Brass Promesh

material description

Scale mesh consists of single scales which are interlinked with a ring to a light flexible metal mesh.

Custom-made measurements on specific request.

- scale diameter: 5,8mm

- material: brass

- haptic: textile flowing, soft to the touch

From: http://www.stylepark.com/en/manufacturer/promesh

Thursday, 2 July 2015

Aluminium

Aluminium is a remarkable material. It has a unique combination of properties that make it suitable for many different applications in various alloy forms.

Aluminium is a light metal whose strength, corrosive and decorating properties can be improved by alloying with various other metals. It has good tensile strength over a wide range of temperatures and has excellent corrosion resistance. When aluminium is exposed to air, a thin, glass-hard oxidised film forms on the surface. This oxide film clings tenaciously to the metal's surface, presenting an effective barrier to the elements. Surface coating can make corrosion resistance even more effective.

Aluminium is an excellent conductor of heat and electricity. It is highly reflective of light, heat, radiant energy and electric waves and is non-magnetic. It is non-sparking, does not ignite or burn and is non-toxic. It can be formed by all known metal working processes, is simple to fabricate and is suitable for joining, bonding and welding. It can be melted, cast, extruded, rolled, formed and machined. It is infinitely recyclable, an important feature in this age of energy and resource saving.

From http://www.google.co.uk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0CCEQFjAA&url=http%3A%2F%2Fwww.micomm.co.za%2Fportfolio%2Fafsa%2Fsurface_finishers.pdf&ei=gVmVVayhJceS7Aa89LPIAw&usg=AFQjCNGhXb6XbVqmavvYRSHbrqF4MTYpdw&sig2=xpnmuakmuN5D8IvB6qmaHg

Aluminium is a light metal whose strength, corrosive and decorating properties can be improved by alloying with various other metals. It has good tensile strength over a wide range of temperatures and has excellent corrosion resistance. When aluminium is exposed to air, a thin, glass-hard oxidised film forms on the surface. This oxide film clings tenaciously to the metal's surface, presenting an effective barrier to the elements. Surface coating can make corrosion resistance even more effective.

Aluminium is an excellent conductor of heat and electricity. It is highly reflective of light, heat, radiant energy and electric waves and is non-magnetic. It is non-sparking, does not ignite or burn and is non-toxic. It can be formed by all known metal working processes, is simple to fabricate and is suitable for joining, bonding and welding. It can be melted, cast, extruded, rolled, formed and machined. It is infinitely recyclable, an important feature in this age of energy and resource saving.

From http://www.google.co.uk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0CCEQFjAA&url=http%3A%2F%2Fwww.micomm.co.za%2Fportfolio%2Fafsa%2Fsurface_finishers.pdf&ei=gVmVVayhJceS7Aa89LPIAw&usg=AFQjCNGhXb6XbVqmavvYRSHbrqF4MTYpdw&sig2=xpnmuakmuN5D8IvB6qmaHg

Patina

Unfinished cast metals weather

well in most instances. Cast iron, aluminum, and bronze will last many

decades with little change if left unfinished. The natural changes in

metals due to atmospheric exposure is called patination. A metals patina

is actually a thin layer of oxides of the metal, the products of

corrosion, that acts to slow down further corrosion.

Unfinished cast metals weather

well in most instances. Cast iron, aluminum, and bronze will last many

decades with little change if left unfinished. The natural changes in

metals due to atmospheric exposure is called patination. A metals patina

is actually a thin layer of oxides of the metal, the products of

corrosion, that acts to slow down further corrosion.

On cast iron the patina is iron

oxide ( to the chemist it's iron oxide to the rest of us it's just

rust). Cast iron rusts extremely quickly. In fact cast iron will begin

to rust when the relative humidity exceeds about 64%! Unlike steel,

however, the rust on cast iron is not invasive but will

act like a coating to prevent deep rusting. Therefore rusting on cast

iron gratings in no way harms their structural integrity. The patination

of cast iron grates goes through a predictable set of stages. The

duration of each stage depends on local moisture conditions and the

amount of foot traffic. So grates will progress slower in the desert

than at the beach but the process is inevitable regardless of location.

Natural Aluminum grates get a coating of aluminum

oxide. which is very hard. This thin transparent patina keeps aluminum

grates looking bright for years. The photo at right shows an unfinished

aluminum grate after three years near the ocean in Florida.

Bronze is well known for its patinas. The natural

patination of bronze is unpredictable and is part of its charm. Colors

arising from the oxidation of bronze range from pale greens and yellows

to white to turquoise to dark brown. Most very dark bronze patinas are

produced artificially by chemical process.

Etched Mirror

Etching refers to the technique of creating art on the surface of

glass by applying acidic, caustic, or frosted glass.

Etching refers to the technique of creating art on the surface of

glass by applying acidic, caustic, or frosted glass.abrasive substances. Traditionally this is done after the glass is blown or cast, although mold-etching has replaced some forms of surface etching. The removal of minute amounts of glass causes the characteristic rough surface and translucent quality of

Techniques

Various techniques are used to achieve an etched surface in glass, whether for artistic effect, or simply to create a translucent surface.

Acid etching is done using hexafluorosilicic acid (H2SiF6) which, when anhydrous, is colourless. The acid is prepared by dissolving silica in a mixture of hydrofluoric acid, quartz powder, calcium fluoride, and concentrated sulfuric acid derived after heating.

Glass etching cream is used by hobbyists as it is generally easier to use than acid. Available from art supply stores, it consists of fluoride compounds, such as hydrogen fluoride and sodium fluoride (which are still very dangerous). As the types of acids used in this process are extremely hazardous, abrasive methods have gained popularity.

Abrasive blasting ("sandblasting") is another common technique for creating patterns in glassware, creating a "frosted" look to the glass. It is often used commercially. High pressure air mixed with an abrasive material cuts away at the glass surface to create the desired effect. The longer the stream of air and abrasive material are focused in one spot, the deeper the cut.

Leptat glass is glass that has been etched using a patented acid process. Leptat takes its name from the Czech word meaning "to etch", because the technique was inspired by a Czechoslovakian glass exhibit viewed at a past World’s Fair in Osaka, Japan, and patented in the United States by Bernard E. Gruenke, Jr.[1] of the Conrad Schmitt Studios. Abstract, figural, contemporary, and traditional designs have been executed in Leptat glass. A secondary design or pattern is sometimes etched more lightly into the negative areas, for further interest. Gold leaf or colored enamels also can be inlaid to highlight the designs. The Leptat technique allows the glass to reflect light from many surfaces, like a jewel-cut gem.

Mold etching In the 1920s a mold-etch process was invented, in which art was etched directly into the mold, so that each cast piece emerged from the mold with the texture already on the surface of the glass. This reduced manufacturing costs and, combined with a wider use of colored glass, led to cheap glassware in the 1930s, which later became known as Depression glass.

Frost Etching is the process in which vinyl window material is cut to produce a pattern and then applied to a window to give a frosted patterned effect.

From https://en.wikipedia.org/wiki/Glass_etching

Wednesday, 1 July 2015

Stainless Steel 3D Printing

1) 3D printing in stainless steel - A Prometal 3D printing machine uses

an inkjet head to deposit an organic binder onto a stainless steel

powder surface. Each layer of powder is adhered in succession until an

object is formed. After the printing has finished the object is placed

in an oven to cure the binder.

2) Infusion - Objects are taken from the ProMetal 3D printing chamber and excess stainless steel powder is removed. These objects are then transfered into a furnace container with bronze. This is heated in a furnace at a high temperature to infuse the bronze into the porous stainless steel objects. This produces a solid metal object that is a hybrid of stainless steel and bronze.

3) Finishing - The object is bead blasted to smooth the surface after the infusing process.

From http://www.ponoko.com/make-and-sell/show-material/239-3d-printed-stainless-steel

2) Infusion - Objects are taken from the ProMetal 3D printing chamber and excess stainless steel powder is removed. These objects are then transfered into a furnace container with bronze. This is heated in a furnace at a high temperature to infuse the bronze into the porous stainless steel objects. This produces a solid metal object that is a hybrid of stainless steel and bronze.

3) Finishing - The object is bead blasted to smooth the surface after the infusing process.

From http://www.ponoko.com/make-and-sell/show-material/239-3d-printed-stainless-steel

Translucent Concrete

Translucent concrete (also: light-transmitting concrete) is a concrete based building material with optical fibers.

Light is conducted through the stone from one end to the other.

Therefore the fibers have to go through the whole object. This results

into a certain light pattern on the other surface, depending on the

fiber structure. Shadows cast onto one side appear as silhouettes

through the material.[1]

Translucent concrete (also: light-transmitting concrete) is a concrete based building material with optical fibers.

Light is conducted through the stone from one end to the other.

Therefore the fibers have to go through the whole object. This results

into a certain light pattern on the other surface, depending on the

fiber structure. Shadows cast onto one side appear as silhouettes

through the material.[1]light-transmissive properties due to embedded light optical elements — usually

Translucent concrete is used in fine architecture as a façade material and for cladding of interior walls. Light-transmitting concrete has also been applied to various design products.

Several ways of producing translucent concrete exist. All are based on a fine grain concrete (ca. 95%) and only 5% light conducting elements that are added during casting process. After setting, the concrete is cut to plates or stones with standard machinery for cutting stone materials.[1][7]

Working with natural light it has to be ensured that enough light is available. Wall mounting systems need to be equipped with some form of lighting, designed to achieve uniform illumination on the full plate surface. Usually mounting systems similar to natural stone panels are used — e.g., LUCEM uses perforated mounting with visible screws, undercut anchors with agraffes or façade anchors.[7]

From: https://en.wikipedia.org/wiki/Translucent_concrete

Metal Foam (closed cell) & (open cell)

Metal foam is a cellular structure made up of a solid metal containing a

large volume fraction of

Metal foam is a cellular structure made up of a solid metal containing a

large volume fraction of gas-filled pores. These pores can either be sealed (closed-cell foam), or they can be an interconnected network (open-cell foam). The closed-cell foam is referred to as metal foams, while the open-cell foam is referred to simply as porous metal.

Metals that Can Be Used

The metal that is commonly used to make metal foams is aluminium. However, other varieties of metals can be used to make the foam, such as titanium and tantalum.

Properties of Metal Foam

The key properties of metal foam are as follows:

- Ultralight material (75–95% of the volume consists of void spaces)

- Very high porosity

- High compression strengths combined with good energy absorption characteristics

- Thermal conductivity is low

- High strength

The main applications of metal foams and porous metals are listed below:

- The closed variety is used for structural applications requiring load-bearing features, and for weight-saving and impact-absorbing structures in vehicles

- The open variety is ideal for vibration and sound absorption, filtration and catalysis at high temperatures, for heat exchange and in medical devices.

- The open variety is also useful in functional applications such as filtration and damping.

- Foam metal is being used as an experimental prosthetic in animals.

- Metal foams with high strengths can act as high-capacity impact-energy absorbers.

- Automotive industry - the foams reduce the number of parts in the car frame, facilitate assembly, thereby reducing costs and improving performance.

Closed Cell

Closed Cell

Electric Paint

Electric Paint is available in 10ml pens and 50ml jars. It is a nontoxic, water based, water soluble, electrically conductive paint, intended for applications with circuits using low DC voltages at low currents. Electric Paint adheres to a wide variety of substrates and is easily removed with water. It is black in color and can be painted over with any material compatible with a water-based paint. Please see the Electric Paint MSDS for precautionary information

Electric Paint is a unique material that can be applied in many different ways, from a paintbrush to common printing processes like screen-printing. To achieve consistent electrical performance it is best to apply Electric Paint in an even layer. If you’re interested in screen printing Electric Paint, it is best to use a textile-type screen in order to achieve a generous layer thickness. We tend to use a 43T screen. Electric Paint is not inkjet printer compatible. For more application tips visit www.bareconductive.com/tutorials

Electric Paint is a water-based paint and acts much like other poster paints. Electric Paint adheres well to wood, paper products, some plastics, corks, textiles and metal. Hydrophobic materials such as some glass and plastics will exhibit poor adhesion, though this can be improved by roughing the surface with sandpaper or similar.

Electric Paint is fast drying at room temperature. This material dries rather than cures and gives off no fumes during the drying process. Drying time can be moderately reduced by placing the material near a low intensity heat source such as an incandescent lamp. Subjecting Electric Paint to a high temperature environment will negatively affect both physical and electrical performance.

Electric Paint is somewhat flexible, but this flexibility depends on two factors, the layer thickness and choice of substrate. Regardless of substrate, a consistently thin layer of paint creates the most flexible circuitry. Areas of paint with wide variation in thickness tend to produce fracturing. Substrates which are flexible, but not stretchy (such as paper) work better than materials like Lycra which stretch in multiple dimensions.

Electric Paint works well as a cold solder joint. Whether used to solder a surface mount or through-hole component onto a circuit board, or to adhere a component to a piece of paper, this material is non-permanent and almost infinitely repairable.These unique properties mean that components can be harvested from projects, cleaned and reused.

From www.bareconductive.com

Electric Paint is a unique material that can be applied in many different ways, from a paintbrush to common printing processes like screen-printing. To achieve consistent electrical performance it is best to apply Electric Paint in an even layer. If you’re interested in screen printing Electric Paint, it is best to use a textile-type screen in order to achieve a generous layer thickness. We tend to use a 43T screen. Electric Paint is not inkjet printer compatible. For more application tips visit www.bareconductive.com/tutorials

Electric Paint is a water-based paint and acts much like other poster paints. Electric Paint adheres well to wood, paper products, some plastics, corks, textiles and metal. Hydrophobic materials such as some glass and plastics will exhibit poor adhesion, though this can be improved by roughing the surface with sandpaper or similar.

Electric Paint is fast drying at room temperature. This material dries rather than cures and gives off no fumes during the drying process. Drying time can be moderately reduced by placing the material near a low intensity heat source such as an incandescent lamp. Subjecting Electric Paint to a high temperature environment will negatively affect both physical and electrical performance.

Electric Paint is somewhat flexible, but this flexibility depends on two factors, the layer thickness and choice of substrate. Regardless of substrate, a consistently thin layer of paint creates the most flexible circuitry. Areas of paint with wide variation in thickness tend to produce fracturing. Substrates which are flexible, but not stretchy (such as paper) work better than materials like Lycra which stretch in multiple dimensions.

Electric Paint works well as a cold solder joint. Whether used to solder a surface mount or through-hole component onto a circuit board, or to adhere a component to a piece of paper, this material is non-permanent and almost infinitely repairable.These unique properties mean that components can be harvested from projects, cleaned and reused.

From www.bareconductive.com

Globomet®

Globomet® is a universal basis material made of metal, and can be shaped into

virtually any form. globomet® can be produced so that it combines various

characteristics that can be accurately customized - the perfect solution

for many applications is in the automobile and mechanical engineering

sectors as well as for catalysis in the chemical industry.

Manufacture

Styropor granules or other organic spheres are coated witha suspension made from metallic powder and binding substances.These green bodies then under go a debinding and sintering process. The result: metallic hollow spheres and hollow sphere structures with particularly thin and even wall thickness.

Characteristics

Depending on the customer's requirements, globomet® can be lightweight, stable, sound-absorbing and porous. All parameters can be customized precisely and reproducibly through the type of metallic powder used, the composition of the metallic powder and binder suspension and the production process.

Futher Processing

The metallic components from globomet® can be sawn, punched,drilled, brazed, welded and cut. Like other metallicmaterials, globomet® is easy to work and process.

From: http://hollomet.com/en/products/globomet.html

Manufacture

Styropor granules or other organic spheres are coated witha suspension made from metallic powder and binding substances.These green bodies then under go a debinding and sintering process. The result: metallic hollow spheres and hollow sphere structures with particularly thin and even wall thickness.

Characteristics

Depending on the customer's requirements, globomet® can be lightweight, stable, sound-absorbing and porous. All parameters can be customized precisely and reproducibly through the type of metallic powder used, the composition of the metallic powder and binder suspension and the production process.

Futher Processing

The metallic components from globomet® can be sawn, punched,drilled, brazed, welded and cut. Like other metallicmaterials, globomet® is easy to work and process.

From: http://hollomet.com/en/products/globomet.html

Cellular metals and metal foams

The possibilities for manufacturing metal foams or other porous metallic structures are reviewed. The various manufacturing processes are classified according to the state of matter in which the metal is processed — solid, liquid, gaseous or ionised. Liquid metal can be foamed directly by injecting gas or gas-releasing blowing agents, or by producing supersaturated metal–gas solutions. Indirect methods include investment casting, the use of space-holding filler materials or melting of powder compacts which contain a blowing agent. If inert gas is entrapped in powder compacts, a subsequent heat treatment can produce cellular metals even in the solid state. The same holds for various sintering methods, metal powder slurry foaming, or extrusion and sintering of polymer/powder mixtures. Finally, electro-deposition or metal vapour deposition also allow for the production of highly porous metallic structures. The various ways for characterising the properties of cellular metals are reviewed in second section of this paper. Non-destructive as well as destructive methods are described. Finally, the various application fields for cellular metals are discussed. They are divided into structural and functional applications and are treated according to their relevance for the different industrial sectors.

http://www.sciencedirect.com/science/article/pii/S0079642500000025

Subscribe to:

Comments (Atom)